Welcome

As you browse our service offerings, you will see that we offer

multiple levels of products and services, including:

|

Facility Assessments for Power Quality |

|

Combining PQ and Energy Efficiency |

|

Design Consulting |

|

Testing |

|

Voltage Sag Standard Certification |

|

Training |

|

Autonomous Robotic Site Surveys |

For more information, contact PQservices@epri.com

Power Quality Facility Assessments

EPRI’s Facility Assessment Team specializes in on-site Power Quality evaluations—over 300 conducted through 2019. EPRI’s team specializes in reducing process downtime and maximizing production output. Facility assessments may involve a few targeted processes or the entire plant. Our experience in solving power quality issues is deep and broad.

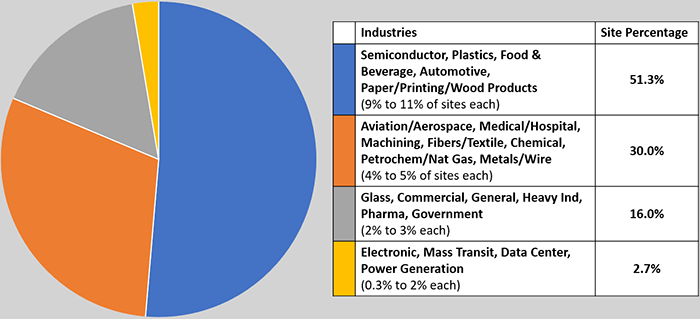

EPRI’s 300+ Facility Assessments by Industry

From a power quality standpoint, EPRI’s Industrial Assessment Team understands both the control systems in an industrial plant and utility systems outside the facility. While others practice power quality as “general practitioners,” EPRI’s team has been referred to as the “neurosurgeons” in the field. Our team can drill deep into power quality issues and provide detailed solutions that can harden an industrial plant to its specific power quality environment. Many times, we can save customers hundreds of thousands of dollars by recommending the best low-cost solution to harden their industrial processes against power quality issues.

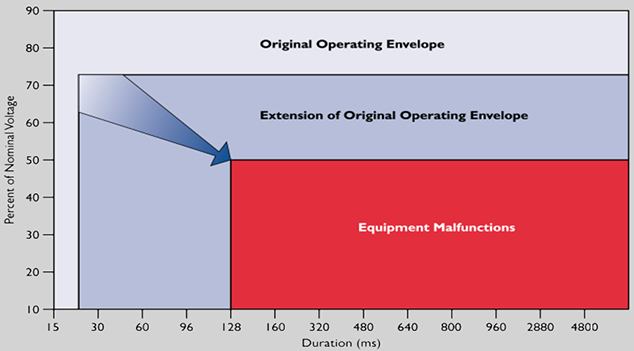

EPRI’s PQ Services Group employs the concept of “Extending the Operating Envelope” of industrial equipment operation during voltage sags. This concept involves helping industrial plants and equipment designers reduce the area in which equipment malfunctions by enabling the equipment to ride through deeper and longer voltage sags.

Concept of Extending Operating Envelope of Industrial Equipment or Process

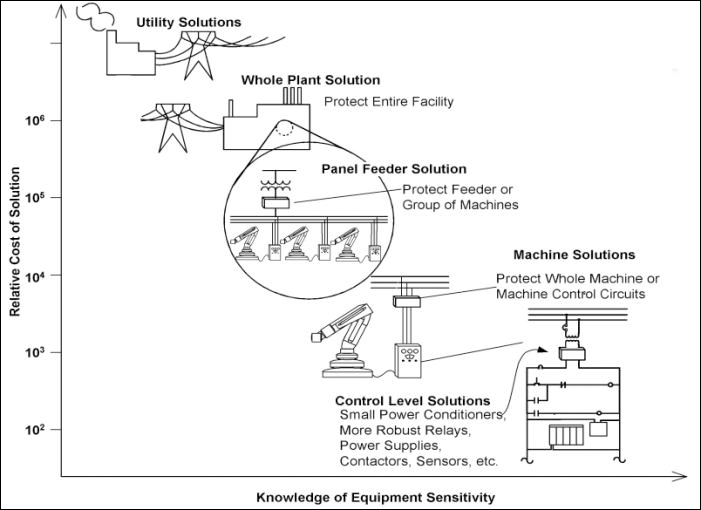

EPRI’s experience provides unparalleled expertise in identifying the sources of process sensitivity and recommending solutions—from the utility, plant, panel, and machine to the individual control components. With our expertise in equipment and component assemblies, we enable our clients to consider options for lower-cost solutions.

EPRI’s Approach Enables Process Hardening at Multiple Levels

Combining PQ and Energy Efficiency

When requested, EPRI’s Industrial Team can combine the goals of improving power quality performance and energy efficiency when conducting an assessment. Energy efficiency assessments may include traditional areas of energy efficiency Assessment areas (insulation, waste heat, drive applications, motors, lighting, air leaks, and heat recovery). In addition, EPRI can provide initial energy-management system (EMS) activities for determining significant energy uses, determining or verifying a plant’s key performance indicators (KPIs) and energy performance indicators (EnPIs), and creating a plant baseline model that considers energy use, production, and relevant variables per ISO 50001 and the Superior Energy Performance Certification requirements.

Design Consulting

Known power quality sensitivities are quite often accounted for in the design of industrial processes. EPRI offers its knowledge of component, equipment, and process PQ sensitivities as a service to original equipment manufacturers (OEMs) through a review of process-control designs prior to manufacturing. Thus, equipment and process designs may be robust to variations in power quality as built, requiring no PQ mitigation after installation.

Testing

EPRI maintains comprehensive test laboratories and mobile test tools, which enable expert power quality testing (voltage sags, line transients, and electromagnetic interference), both in the lab and onsite. We pioneered the technology behind the EPRI voltage sag generator (also called the PortoSag) and routinely test industrial equipment loads that require three-phase power (up to 200 amps of current).

Voltage Sag Standards Certification

EPRI can quickly certify that a process component or machine complies with IEEE 1668 and/or SEMI F47. EPRI established a certification program to test manufacturer equipment per established power quality standards. PQ Star certification is available for suppliers of semiconductor equipment.

Training

EPRI offers training in all aspects of power quality at its location in Knoxville, Tennessee, at off-site locations around the world as requested, and even online through its video series on power quality topics.

Autonomous Robotic Site Surveys

If you have an issue with electromagnetic interference or electric fields that needs to be characterized and isolated, the EPRI “PQ Robot” (the Big Autonomous Mobile Measurement Platform, or BAMMP) can help you get to the root of the issue. Navigating with high-precision (+/- 2CM) GPS (outdoors) or LIDAR (indoors), the BAMMP autonomously measures several parameters, including electric fields, radio frequency interference (RFI), the lighting spectrum, and even the presence and emissivity of radioactive materials or residues. The data obtained may be visualized as a heat map on aerial imagery or a map. Characterizations can be done before and after remediation.

For more information, contact: PQservices@epri.com